| SKU |

|

|

|

|

|

|

|

|

Price in MDL | |

|---|---|---|---|---|---|---|---|---|---|---|

| 575 125 | 125 | 32 | 157 | 33 | 92.5x64 | 75x45 | 12x8.5 | 150 | 150 MDL | Add to cart |

| 575 100 | 100 | 32 | 131 | 36 | 92.5x64 | 75x45 | 12x8.5 | 130 | 120 MDL | Add to cart |

| 575 075 | 75 | 32 | 107 | 30 | 92.5x64 | 75x45 | 12x8.5 | 100 | 100 MDL | Add to cart |

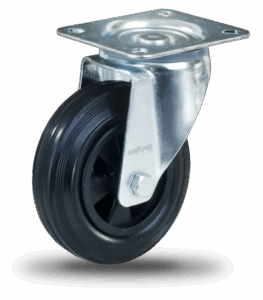

Industrial swivel wheel «special» 575

The Medium-Duty «special» 575 series is a line of industrial wheels with a tread made of elastic rubber and a nylon rim. These wheels feature enhanced wear resistance, excellent vibration absorption, and good shock-absorbing properties, while leaving no marks or streaks on the floor.

Operating temperature range: from -20°C to +70°C.

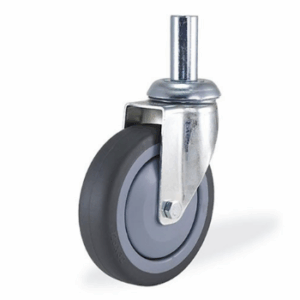

The swivel wheel is equipped with a bracket that includes a double ball bearing in the swivel assembly, allowing for easy changes in movement direction. It is used to provide maneuverability for trolleys and equipment.

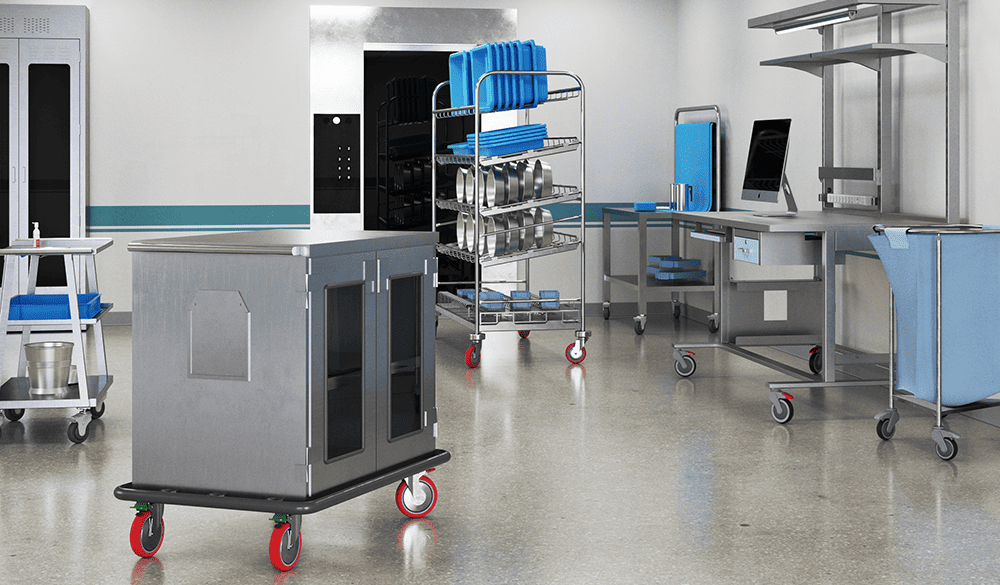

Wheels made of elastic rubber are most commonly installed on equipment used in environments with high sanitary requirements, such as medical stretchers, shopping carts, and warehouse or transport trolleys used in the food service industry.

ELASTIC RUBBER (BLUE) / NYLON (BLACK) WHEELS

• Swivel bracket made of galvanized steel, 2.5 mm thick.

• Top plate mounting for four bolts.

• Double ball bearing in the swivel head.

• Tread made of elastic rubber (blue) that leaves no marks on the floor surface.

• Rim made of nylon (black).

• Roller bearing in the axle effectively handles both axial and radial loads.

• Medium-duty industrial wheels. Load capacity up to 150 kg.

• Food service industry.

• Medical field.

• Storage racks, shelves, warehouse and transport trolleys in the food service industry.

• Shopping carts.

• Medical stretchers.

Information about casters and operating conditions

• Casters are replaceable technical components mounted on equipment, platform carts, and similar devices to provide mobility. This information applies to swivel casters intended exclusively for use on non-motorized transport units and equipment (hereafter referred to as “units”) that are typically stationary and moved at speeds not exceeding 4 km/h.

• Operating conditions primarily include technically correct installation:

– The caster must be securely attached to the unit at all designated mounting points.

– Swivel casters must be installed with their swivel axis in a vertical position.

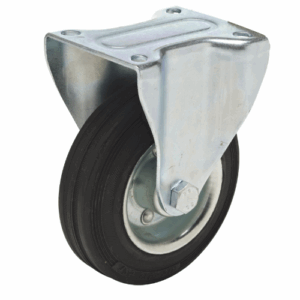

– Fixed (rigid) casters must be mounted so that their wheel axes lie on parallel lines.

– All swivel casters installed on a unit must be of the same type.

– The load on a single caster is calculated using the formula:

Q = ((M + m) / (n – 1)) × W

Where:

Q – load on one caster

M – weight of the transported load

m – weight of the cart

n – number of casters

W – safety factor (>1 under non-standard operating conditions)

• The caster, bracket, braking and locking systems, as well as the wheel axle, form a single functional assembly.

• A necessary condition for proper caster selection is the availability of data on all potential loads.