| SKU |

|

|

|

|

|

|

|

|

Price in MDL | |

|---|---|---|---|---|---|---|---|---|---|---|

| 3802 CTR 100 F18 | 100 | 25 | 133 | 43 | 100x85 | 80x60 | 12,5x9,3 | 120 | 1 MDL | Add to cart |

| 3802 CTR 125 F18 | 125 | 40 | 161 | 41 | 100x85 | 80x60 | 12,5x9,3 | 150 | 1 MDL | Add to cart |

| 3802 CTR 150 F18 | 150 | 45 | 183 | 44 | 100x85 | 80x60 | 12,5x9,3 | 180 | 1 MDL | Add to cart |

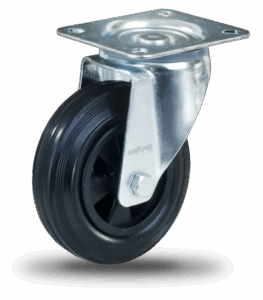

Industrial swivel caster with brake 3802 CTR F18

The 3802 CTR F18 medium-duty series is a range of industrial swivel casters made of thermoelastic rubber. The wheel rim is made of polypropylene. The casters are resistant to impact loads, absorb vibrations, do not damage or mark the floor surface, have low rolling resistance on uneven surfaces, and are resistant to many chemicals except oils.

Temperature range: from -20°C to +60°C.

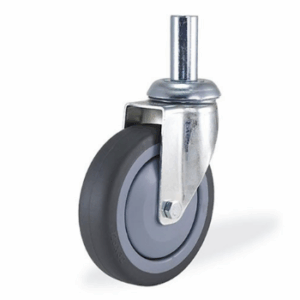

The swivel casters provide excellent maneuverability thanks to the high-quality rubber tread and the bracket design with a double ball bearing in the swivel head, ensuring smooth rotation under load. The swivel casters are additionally equipped with a brake for fixing platform trolleys during parking.

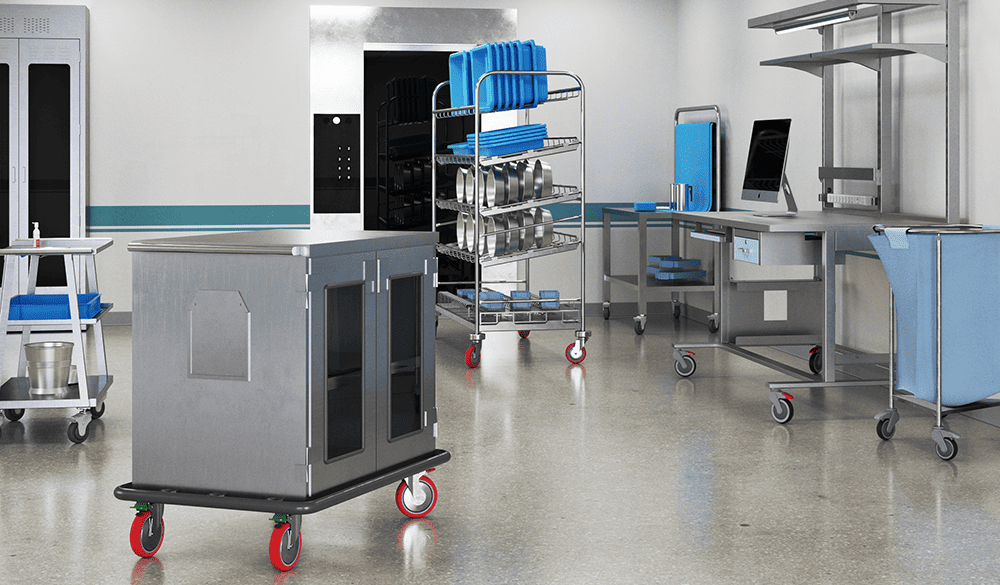

Casters made of thermoelastic rubber are used on medical, commercial, office, and laboratory equipment, as well as on platform trolleys operated on delicate floor surfaces such as linoleum, mosaic floors, ceramic tiles, parquet, and laminate.

THERMOELASTIC RUBBER / POLYPROPYLENE CASTERS

• Swivel bracket made of zinc-plated steel.

• Top plate mounting with four holes.

• Double ball bearing in the swivel head ensures smooth rotation under load.

• Equipped with a brake mechanism.

• Tread made of thermoelastic rubber.

• Wheel rim made of polypropylene, resistant to moisture, salt and acid solutions; absorbs vibrations and minor impacts.

• Plain bearing in the wheel hub provides excellent axial and radial load capacity.

• Medium-duty industrial casters. Load capacity up to 180 kg.

• Medical applications

• Service industry

• Stretchers and mobile hospital furniture.

• Cleaning trolleys for hotels.

• Shopping trolleys.

• Laundry trolleys.

Information about casters and operating conditions

• Casters are replaceable technical components mounted on equipment, platform carts, and similar devices to provide mobility. This information applies to swivel casters intended exclusively for use on non-motorized transport units and equipment (hereafter referred to as “units”) that are typically stationary and moved at speeds not exceeding 4 km/h.

• Operating conditions primarily include technically correct installation:

– The caster must be securely attached to the unit at all designated mounting points.

– Swivel casters must be installed with their swivel axis in a vertical position.

– Fixed (rigid) casters must be mounted so that their wheel axes lie on parallel lines.

– All swivel casters installed on a unit must be of the same type.

– The load on a single caster is calculated using the formula:

Q = ((M + m) / (n – 1)) × W

Where:

Q – load on one caster

M – weight of the transported load

m – weight of the cart

n – number of casters

W – safety factor (>1 under non-standard operating conditions)

• The caster, bracket, braking and locking systems, as well as the wheel axle, form a single functional assembly.

• A necessary condition for proper caster selection is the availability of data on all potential loads.