| SKU |

|

|

|

|

|

|

|

|

Price in MDL | |

|---|---|---|---|---|---|---|---|---|---|---|

| 3302 MMB 100 F18 | 100 | 30 | 130 | 42 | 100x85 | 80x60 | 17x9 | 100 | 1 MDL | Add to cart |

| 3302 MMB 125 F18 | 125 | 37.5 | 156 | 38 | 100x85 | 80x60 | 17x9 | 150 | 1 MDL | Add to cart |

| 3302 MMB 150 F18 | 150 | 40 | 182 | 38 | 100x85 | 80x60 | 17x9 | 180 | 1 MDL | Add to cart |

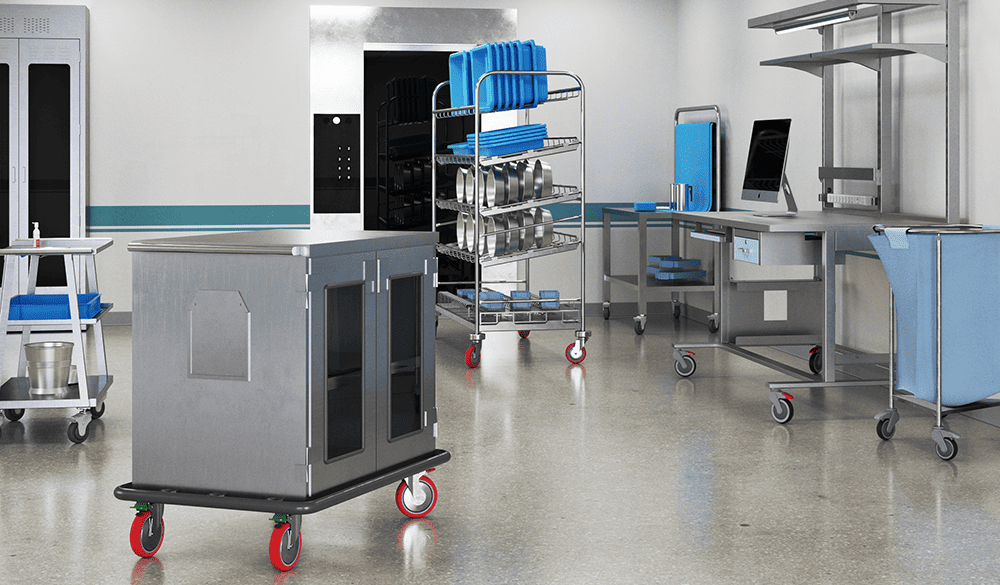

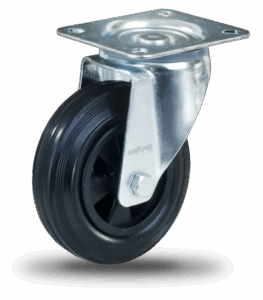

Industrial swivel caster with brake 3302 MMB F18

Medium duty series 3302 MMB F18 — is a series of industrial casters made of white polypropylene. The polypropylene casters in this series can withstand high loads. The material’s high wear resistance ensures a long service life.

Temperature range: from -20°C to +60°C

Thanks to the swivel mechanism, the casters can easily change direction and turn. A ball bearing in the axle contributes to smooth rotation.

The swivel casters are additionally equipped with a brake to secure a platform trolley when parked.

White polypropylene casters are most often installed on shopping trolleys used in supermarkets, as well as on other commercial equipment; hotel housekeeping trolleys, etc.

SOLID POLYPROPYLENE CASTERS

• Swivel bracket made of galvanized steel.

• Platform mounting with 4 holes.

• Double-row ball bearing in the swivel head ensures easy rotation under load.

• Equipped with a brake mechanism.

• One-piece solid polypropylene wheel provides excellent strength and light weight.

• Ball bearing in the axle handles axial and radial loads well.

• Medium duty industrial casters. Load capacity up to 180 kg.

• Food service.

• Service sector.

• Medicine

• Commercial equipment.

• Shopping trolleys.

• Hotel housekeeping trolleys.

Information about casters and operating conditions

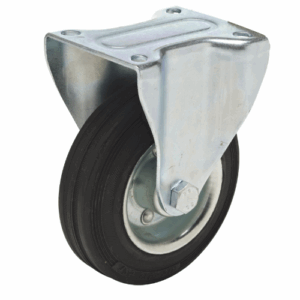

• Casters are replaceable technical components mounted on equipment, platform carts, and similar devices to provide mobility. This information applies to swivel casters intended exclusively for use on non-motorized transport units and equipment (hereafter referred to as “units”) that are typically stationary and moved at speeds not exceeding 4 km/h.

• Operating conditions primarily include technically correct installation:

– The caster must be securely attached to the unit at all designated mounting points.

– Swivel casters must be installed with their swivel axis in a vertical position.

– Fixed (rigid) casters must be mounted so that their wheel axes lie on parallel lines.

– All swivel casters installed on a unit must be of the same type.

– The load on a single caster is calculated using the formula:

Q = ((M + m) / (n – 1)) × W

Where:

Q – load on one caster

M – weight of the transported load

m – weight of the cart

n – number of casters

W – safety factor (>1 under non-standard operating conditions)

• The caster, bracket, braking and locking systems, as well as the wheel axle, form a single functional assembly.

• A necessary condition for proper caster selection is the availability of data on all potential loads.