Phone Number

+373 79-00-39-33Phone Number

+373 79-00-39-33- Industries

- Wheels by Load Capacity

Industrial Wheels – Medium Load Capacity

Up to 240 kg

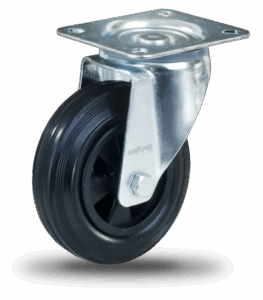

Series «standart» 036

High-quality rubber

Up to 220 kg

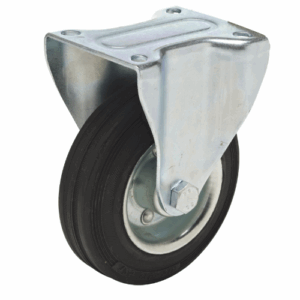

Series «standart» 038

High-quality rubber

Up to 220 kg

Series «standart» 045

High-quality rubber

Up to 230 kg

Series «standart» 047

High-quality rubber

Up to 230 kg

Series «profi» 708

Black rubber / polypropylene PP

Up to 240 kg

Series «profi» 709

Black rubber / polypropylene PP

Up to 240 kg

Series 3302 SLP

Black rubber

Up to 205 kg

Series 3302 SLP F18

Black rubber

Up to 205 kg

Series 3802 CTR

Thermoelastic rubber

Up to 150 kg

Series 3302 PRS

Blue rubber

Up to 150 kg

Series 3302 PRS F18

Blue rubber

Up to 150 kg

Series 3302 MMB

White polypropylene

Up to 150 kg

СЕРИЯ 3302 MMB F18

White polypropylene

Up to 150 kg

Series «special» 747

Polyurethane

Up to 150 kg

Series «special» 748

Polyurethane

Up to 150 kg

Series «special» 749

Polyurethane

Up to 150 kg

Series «special» 575

Elastic rubber

Up to 150 kg

Series «special» 576

Elastic rubber

Up to 150 kg

Series «special» 577

Elastic rubber

Up to 150 kg

Industrial Wheels – Heavy-Duty

Up to 500 kg

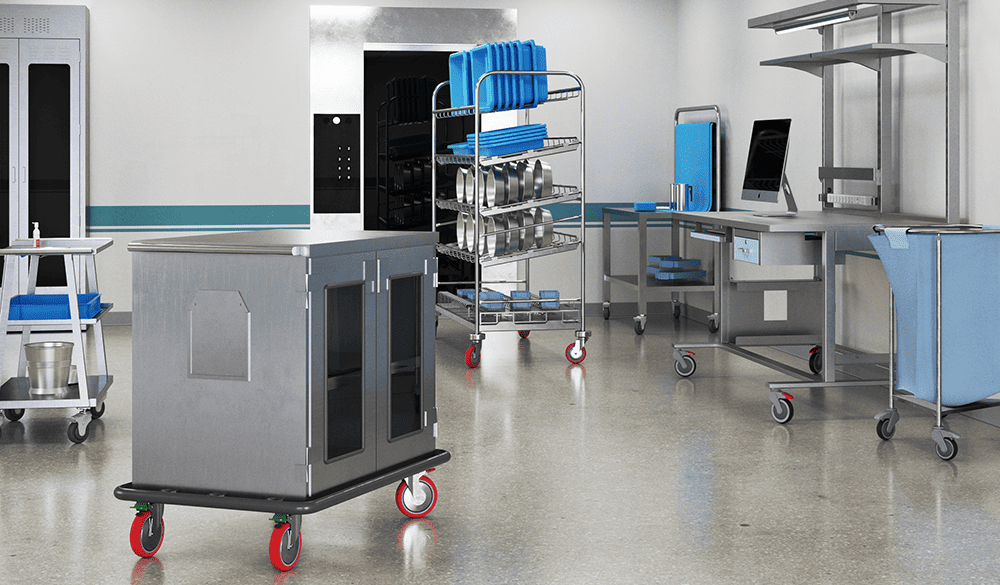

Equipment (Apparatus) Wheels

Up to 140 kg

Series EP01 MKT

Grey thermoplastic rubber

Up to 60 kg

Series EP01 MKT F

Grey thermoplastic rubber

Up to 60 kg

Series EP02 MKT

Grey thermoplastic rubber

Up to 60 kg

Series EP04 MKT

Grey thermoplastic rubber

Up to 60 kg

Series EP04 MKT F

Grey thermoplastic rubber

Up to 60 kg

Series TPR

Polypropylene

Up to 140 kg

Series TPRb

Polypropylene

Up to 140 kg

Furniture Wheels

- Wheels by application

Construction

Series 346

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series 347

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series 348

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series «standart» 036

• Diameter: 85–200 mm

• Load capacity: 55–220 kg

Series «standart» 037

• Diameter: 85–200 mm

• Load capacity: 55–220 kg

Series «standart» 038

• Diameter: 85–200 mm

• Load capacity: 55–220 kg

Series 3302 SLP

• Diameter: 125–200 mm

• Load capacity: 100–205 kg

Series 3302 SLP F18

• Diameter: 125–200 mm

• Load capacity: 100–205 kg

Series «standart» 045

• Diameter: 160–200 mm

• Load capacity: 150–230 kg

Series «standart» 047

• Diameter: 160–200 mm

• Load capacity: 150–230 kg

Series «profi» 708

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 709

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 106

• Diameter: 100–200 mm

• Load capacity: 200–380 kg

Series «profi» 106NL

• Diameter: 100–200 mm

• Load capacity: 200–380 kg

Series «profi» 097

• Diameter: 100–200 mm

• Load capacity: 240–500 kg

Series «profi» 097NL

• Diameter: 100–200 mm

• Load capacity: 240–500 kg

Series 3602 PUR

• Diameter: 100–200 mm

• Load capacity: 200–500 kg

Series 3602 PUR F18

• Diameter: 100–200 mm

• Load capacity: 200–500 kg

Industry

Series «profi» 097

• Diameter: 100–200 mm

• Load capacity: 240–500 kg

Series «profi» 097NL

• Diameter: 100–200 mm

• Load capacity: 240–500 kg

Series «profi» 106

• Diameter: 100–200 mm

• Load capacity: 200–380 kg

Series «profi» 106NL

• Diameter: 100–200 mm

• Load capacity: 200–380 kg

Series «profi» 708

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 709

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series 3302 SLP

• Diameter: 200 mm

• Load capacity: 205 kg

Series 3302 SLP F18

• Diameter: 200 mm

• Load capacity: 205 kg

Series «standart» 036

• Diameter: 125–200 mm

• Load capacity: 100–220 kg

Series «standart» 038

• Diameter: 125–200 mm

• Load capacity: 100–220 kg

Series «standart» 045

• Diameter: 160–200 mm

• Load capacity: 150–230 kg

Series «standart» 047

• Diameter: 160–200 mm

• Load capacity: 150–230 kg

Series 3602 PUR

• Diameter: 100–200 mm

• Load capacity: 200–500 kg

Series 3602 PUR F18

• Diameter: 100–200 mm

• Load capacity: 200–500 kg

Housing and public utilities

Series «standart» 036

• Diameter: 125–200 mm

• Load capacity: 100–220 kg

Series «standart» 038

• Diameter: 125–200 mm

• Load capacity: 100–220 kg

Series 3302 SLP

• Diameter: 125–200 mm

• Load capacity: 100–205 kg

Series 3302 SLP F18

• Diameter: 125–200 mm

• Load capacity: 100–205 kg

Series «profi» 708

Diameter: 160-200mm

Load: 180-240kg

Series «profi» 709

Diameter: 160-200mm

Load: 180-240kg

Logistics / Warehousing

Series 346

• Diameter: 100-200 mm

• Load capacity: 80-250 kg

Series 347

• Diameter: 100-200 mm

• Load capacity: 80-250 kg

Series 348

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series «profi» 097

• Diameter: 100–200 mm

• Load capacity: 240–500 kg

Series «profi» 097NL

• Diameter: 100–200 mm

• Load capacity: 240–500 kg

Series «standart» 036

• Diameter: 100–200 mm

• Load capacity: 70–220 kg

Series «standart» 037

• Diameter: 100–200 mm

• Load capacity: 70–220 kg

Series «standart» 038

• Diameter: 100–200 mm

• Load capacity: 70–220 kg

Series «standart» 045

• Diameter: 160–200 mm

• Load capacity: 150–230 kg

Series «standart» 047

• Diameter: 160–200 mm

• Load capacity: 150–230 kg

Series «profi» 708

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 709

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 106

• Diameter: 100–200 mm

• Load capacity: 200–380 kg

Series «profi» 106NL

• Diameter: 100–200 mm

• Load capacity: 200–380 kg

Series 3302 SLP

• Diameter: 125–200 mm

• Load capacity: 100–205 kg

Series 3302 SLP F18

• Diameter: 125–200 mm

• Load capacity: 100–205 kg

Series 3602 PUR

• Diameter: 100–200 mm

• Load capacity: 200–500 kg

Series 3602 PUR F18

• Diameter: 100–200 mm

• Load capacity: 200–500 kg

Garden and gardening

Series «standart» 036

• Diameter: 80–200 mm

• Load capacity: 55–200 kg

Series «standart» 037

• Diameter: 80–200 mm

• Load capacity: 55–200 kg

Series «standart» 038

• Diameter: 80–200 mm

• Load capacity: 55–200 kg

Series 3302 SLP

• Diameter: 125–150 mm

• Load capacity: 100–135 kg

Series 3302 SLP F18

• Diameter: 125–150 mm

• Load capacity: 100–135 kg

Series «profi» 708

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 709

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series 3602 PUR

• Diameter: 125 mm

• Load capacity: 250 kg

Series 3602 PUR F18

• Diameter: 125 mm

• Load capacity: 250 kg

Commercial equipment

Series 346

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series 347

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series 348

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series «standart» 036

• Diameter: 125–150 mm

• Load capacity: 100–150 kg

Series «standart» 038

• Diameter: 125–150 mm

• Load capacity: 100–150 kg

Series 3302 SLP

• Diameter: 125–150 mm

• Load capacity: 100–135 kg

Series 3302 SLP F18

• Diameter: 125–150 mm

• Load capacity: 100–135 kg

Series «profi» 708

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 709

• Diameter: 160–200 mm

• Load capacity: 180–240 kg

Series «profi» 106

• Diameter: 125 mm

• Load capacity: 240 kg

Series «profi» 106NL

• Diameter: 125 mm

• Load capacity: 240 kg

Series 3602 PUR

• Diameter: 125 mm

• Load capacity: 250 kg

Series 3602 PUR F18

• Diameter: 125 mm

• Load capacity: 250 kg

Series 3802 CTR

• Diameter: 125 mm

• Load capacity: 150 kg

Series 3802 CTR F18

• Diameter: 125 mm

• Load capacity: 150 kg

Series 3302 PRS

• Diameter: 125 mm

• Load capacity: 150 kg

Series 3302 PRS F18

• Diameter: 125 mm

• Load capacity: 150 kg

Series 3302 MMB

• Diameter: 125 mm

• Load capacity: 150 kg

Series 3302 MMB F18

• Diameter: 125 mm

• Load capacity: 150 kg

Series 2800 MTR

• Diameter: 80–150 mm

• Load capacity: 90–130 kg

Series 2800 MTR F18

• Diameter: 80–150 mm

• Load capacity: 90–130 kg

Series 2805 MTR

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series 2805 MTR F18

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series EP01 MKT

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP01 MKT F

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP02 MKT

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP04 MKT

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP04 MKT F

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Catering

Series 346

• Diameter: 80-125 mm

• Load capacity: 80-120 kg

Series 347

• Diameter: 80-125 mm

• Load capacity: 80-120 kg

Series 348

• Diameter: 80-200 mm

• Load capacity: 65-250 kg

Series TPR

• Diameter: 100–125 mm

• Load capacity: 100–140 kg

Series TPRb

• Diameter: 100–125 mm

• Load capacity: 100–140 kg

Series EP01 MKT

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP01 MKT F

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP02 MKT

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP04 MKT

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series EP04 MKT F

• Diameter: 75–100 mm

• Load capacity: 50–60 kg

Series 3302 MMB

• Diameter: 125 mm

• Load capacity: 150 kg

СЕРИЯ 3302 MMB F18

• Diameter: 125 mm

• Load capacity: 150 kg

Series «special» 747

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Series «special» 748

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Series «special» 749

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Series «special» 575

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Series «special» 576

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Series «special» 577

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Medicine

Series 2800 MTR

• Diameter: 80–150 mm

• Load capacity: 90–130 kg

Series 2800 MTR F18

• Diameter: 80–150 mm

• Load capacity: 90–130 kg

Series 3802 CTR

• Diameter: 100–125 mm

• Load capacity: 120–150 kg

Series 3802 CTR F18

• Diameter: 100–125 mm

• Load capacity: 120–150 kg

Series «special» 575

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Series «special» 577

• Diameter: 75–125 mm

• Load capacity: 100–150 kg

Series 2805 MTR

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series 2805 MTR F18

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series EP01 MKT

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series EP01 MKT F

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series EP02 MKT

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series EP04 MKT

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series EP04 MKT F

• Diameter: 80–125 mm

• Load capacity: 90–110 kg

Series TPR

• Diameter: 100–125 mm

• Load capacity: 100–140 kg

Series TPRb

• Diameter: 100–125 mm

• Load capacity: 100–140 kg

Series 3302 MMB

• Diameter: 125 mm

• Load capacity: 150 kg

Series 3302 MMB F18

• Diameter: 125 mm

• Load capacity: 150 kg

Furniture

Series G1801PPB 050

• Diameter: 50 mm

• Load capacity: 40 kg

Series G1801PPB 050 F02

• Diameter: 50 mm

• Load capacity: 40 kg

Series S1801PPB 050

• Diameter: 50 mm

• Load capacity: 40 kg

Series S1801PPB 050 F01

• Diameter: 50 mm

• Load capacity: 40 kg

Series S1802PPB 050

• Diameter: 50 mm

• Load capacity: 40 kg

Series S1802 PPB 050 F01

• Diameter: 50 mm

• Load capacity: 40 kg

- About us

- Contacts