| SKU |

|

|

|

|

|

|

|

|

Price in MDL | |

|---|---|---|---|---|---|---|---|---|---|---|

| 037 20 080 | 80 | 22 | 110 | 507 | 102x84 | 80x60 | 9x14 | 55 | 50 MDL | Add to cart |

| 037 20 100 | 100 | 30 | 126 | 507 | 102x84 | 80x60 | 9x14 | 70 | 60 MDL | Add to cart |

| 037 20 125 | 125 | 34 | 150 | 507 | 102x84 | 80x60 | 9x14 | 100 | 75 MDL | Add to cart |

| 037 20 160 | 150 | 36 | 190 | 507 | 135x105 | 105x75 | 10.3x13.5 | 150 | 150 MDL | Add to cart |

| 037 20 200 | 200 | 44 | 233 | 507 | 135x105 | 105x75 | 10.3x13.5 | 220 | 220 MDL | Add to cart |

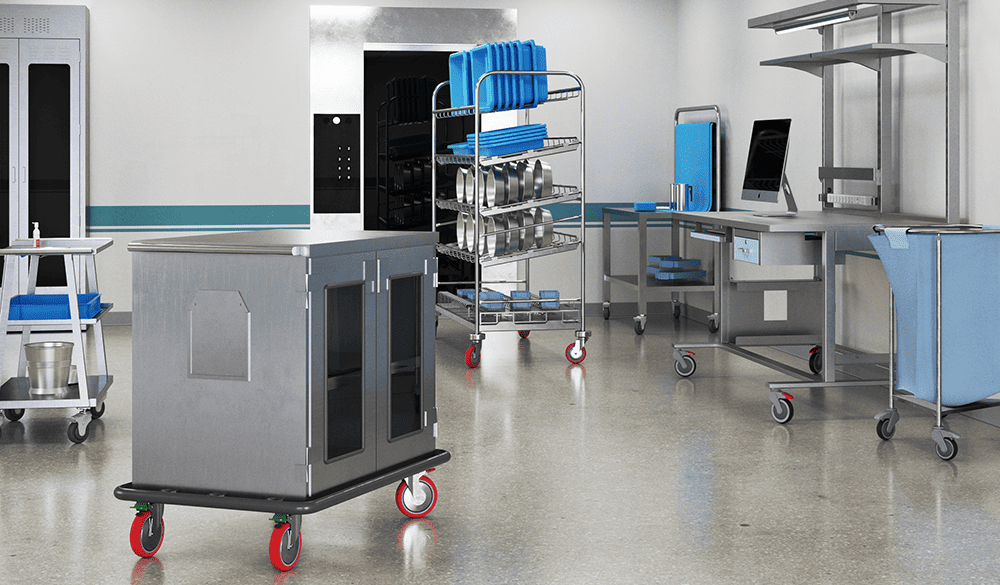

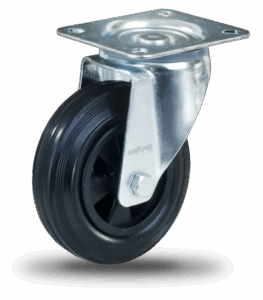

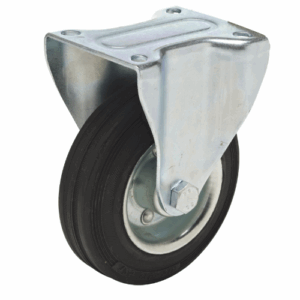

Industrial fixed caster «standart» 037

Medium-duty standart» series is a popular line of industrial casters made from rigid black rubber. The use of this material, along with a rim made of durable galvanized steel, allows the casters to perform reliably under challenging conditions such as high humidity and rough, uneven surfaces composed of various materials. The rubber maintains its properties across a wide temperature range: from -10°C to +50°C.

A distinctive feature of the fixed caster design is the non-swiveling bracket with a mounting plate (4-bolt configuration). Fixed casters are used to adjust the maneuverability of carts or to ensure stable, straight-line movement.

RIGID BLACK RUBBER/STEEL CASTERS

• Fixed bracket made of galvanized steel, thickness 2.0/2.5 mm

• Platform mounting with 4-bolt configuration

• Tread made of rigid black rubber, resistant to wear and deformation; ensures low rolling resistance on uneven surfaces

• Rim made of durable galvanized sheet steel, highly resistant to external impacts

• Roller bearing in the axle effectively handles both axial and radial loads

• Medium-duty industrial casters. Load capacity up to 220 kg.

• Construction

• Manufacturing / Industrial sector

• Public utilities and housing services

• Logistics and warehousing

• Commercial and facility services

• Used to adjust cart maneuverability or ensure stable straight-line movement.

Information about casters and operating conditions

• Casters are replaceable technical components mounted on equipment, platform carts, and similar devices to provide mobility. This information applies to swivel casters intended exclusively for use on non-motorized transport units and equipment (hereafter referred to as “units”) that are typically stationary and moved at speeds not exceeding 4 km/h.

• Operating conditions primarily include technically correct installation:

– The caster must be securely attached to the unit at all designated mounting points.

– Swivel casters must be installed with their swivel axis in a vertical position.

– Fixed (rigid) casters must be mounted so that their wheel axes lie on parallel lines.

– All swivel casters installed on a unit must be of the same type.

– The load on a single caster is calculated using the formula:

Q = ((M + m) / (n – 1)) × W

Where:

Q – load on one caster

M – weight of the transported load

m – weight of the cart

n – number of casters

W – safety factor (>1 under non-standard operating conditions)

• The caster, bracket, braking and locking systems, as well as the wheel axle, form a single functional assembly.

• A necessary condition for proper caster selection is the availability of data on all potential loads.